- Floor No.: PLOT-2206, TP-508 Ahmedabad, Gujarat, India

- sales@saidrishti.com

- +91 97372 45858

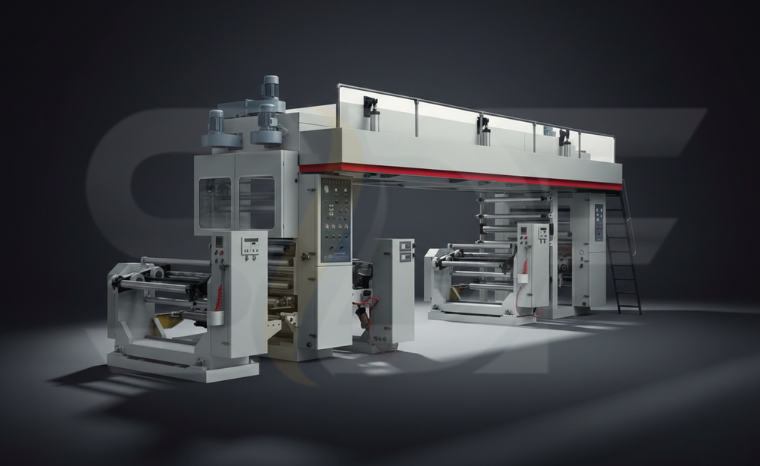

Roto Gravure Printing is a high-speed, high-quality printing process used for producing sharp, consistent images on flexible materials like plastic films, paper, and foils.

The Trim Winder Machine is designed for trimming and rewinding printed banners and flex materials with ease. It offers smooth operation, clean edges, and neat winding – perfect for print shops looking to save time and improve finishing quality.

We are a leading BOPP Self Adhesive Tape Slitting Machine manufacturer and supplier . Our extensive product range also includes Rotogravure printing machines, lamination machines, slitting machines, doctoring and rewinding machines, trim winders, VMCH coating machines, aluminum foil winding machines, and various other machinery for the packaging industry.

Air Shaft with Safety Chuck (Rewind & Unwind): Ensures secure and efficient roll handling during both unwinding and rewinding operations Optional Water Cooling System: Available for heat-sensitive materials and improved thermal management

We provide a high quality range of VMCH Shellac Coating Machines. These machines are appreciated by our clients for their high production speed and low maintenance cost, which greatly enhances its cost effectiveness.

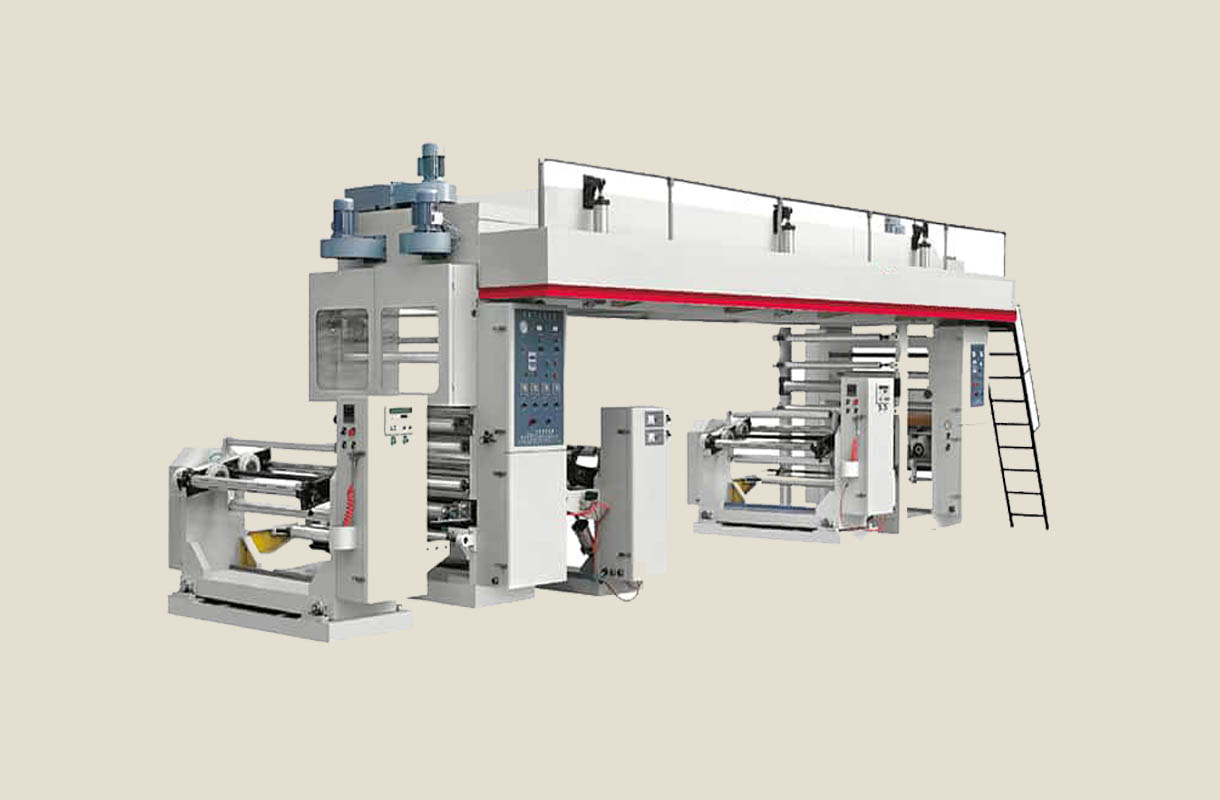

This Heat and Press Laminator is engineered for high-performance lamination using a pneumatic pressure application system on a heated drum surface. The heating drum is dynamically balanced, precision-ground, and hard chrome-plated, and operates in synchronization with the rewinder for smooth processing.

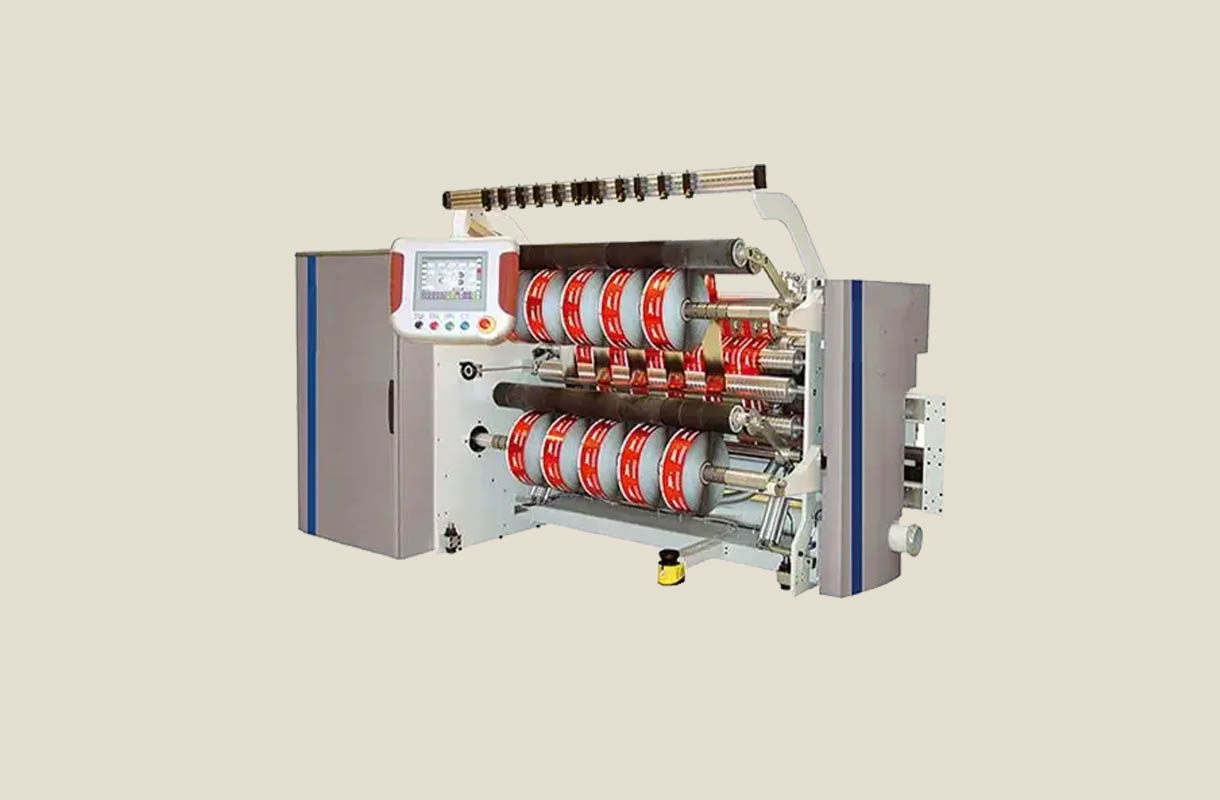

Engineered with advanced design features, this slitter rewinder ensures exceptional quality in the final slit rolls. Its robust construction and high-precision components make it ideal for processing a wide range of flexible packaging materials.

The Machine is suitable for Inkject printing / batch coding on printed & laminated pouches.

Canti Lever type slitter rewinder machine incorporates a range of superior design feature.

Air shaft with safty chuck in rewinding, Air shaft with safty chuck shaft in unwinding.

Being a customer-focused organization, we are engaged in offering a wide assortment of Roll Stretch Wrapping Machines.

Pneumatic pressure application method on hot drum surface. Heating drum is synchronized with rewinder and dynamically balanced.

Years

Experience

To invest in continuous innovation, customer support, and service excellence that ensure long-term satisfaction and partnerships.

To be a global leader in providing innovative, reliable, and high-performance packaging machinery solutions, empowering industries to achieve operational excellence and sustainable growth.

We offer our products and service support all across the globe.

We offer our products and service support all across the globe.

We offer our products and service support all across the globe.