The factors of product durability, visual attractiveness, and protection are very important in the modern competitive manufacturing and packaging world. Lamination Machines are crucial in improving the quality of the products as they are used to bond several layers of different materials with accuracy and uniformity. Due to the adoption of hi-tech technology, the industrial lamination machines are now faster, more efficient, and more reliable when it comes to large-scale production needs.

What Are Lamination Machines?

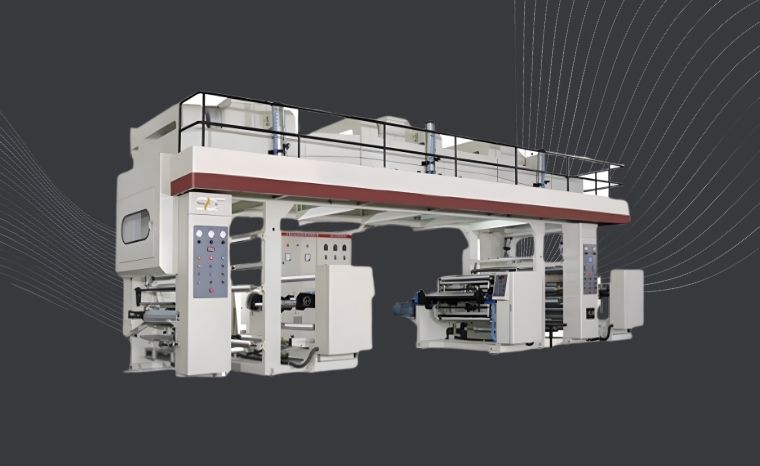

Lamination Machines are industrial processes that are employed to unite two or more layers of materials like films, paper, foil, or fabric with adhesives, heat, or pressure. The lamination process enhances strength, looks, and moisture, chemical, and wear resistance. Lamination machines in industries are structured to operate continuously and therefore deliver even at large production levels.

Relevance of sophisticated Technology in Lamination

Modern Lamination Machines have also been radically changed due to advanced technology. Manufacturers are able to produce identical bonding and perfectly finished surfaces via automated controls, precision coating systems, and effective drying units. Such technological innovations contribute to minimizing human error, the amount of wasted materials, and serving the same level of lamination in long production lines.

Industrial Lamination Machines: Major Characteristics

State-of-the-art Lamination Machines with sophisticated technology have several performance-enhancing features:

- Rapid lamination to run continuous production.

- Accurate application of adhesives and bonded control.

- Developed temperature and pressure control.

- Powerful machine framework for vibration-free performance.

- Digital monitoring control panels.

Such characteristics guarantee a consistent and high-quality lamination process with the highest possible productivity and operation efficiency.

Applications in a Variety of Industries

Industrial Lamination Machines find application in industries that include flexible packaging, printing, food and beverage packaging, pharmaceuticals, textiles, and insulation material. Lamination enhances shelf life and barrier properties in the packaging industry. In printing as well as in decorative use, it increases visual attractiveness and permanency. Lamination machines are incredibly versatile, hence being employed in a wide range of applications in the industrial context.

Advantages of the high-level Lamination Machines

Implementations of the new Lamination Machines have several benefits to manufacturers:

- Enhanced strength of bond and product life.

- Less wastage of adhesive and material.

- Increased speed and efficiency of production.

- Consistent output quality

- Reduced labour reliance and costs of operation.

These benefits allow the businesses to operate at high-quality standards as they achieve growing market demand.

Role in the Continuous Production of Industry

Perpetual production is one of the necessities of contemporary production plants. Advanced Lamination Machines are intended to help maintain continuous operations in which performance is stable throughout the long working hours. There is controlled tension and motorized drive systems that provide smooth material handling to minimize downtime and enhance the efficiency of the entire plant.

Increased Demand for Industrial Lamination Solutions

As more companies are in need of high-quality packaging and industrial material that is durable, the uptake of sophisticated Lamination Machines is increasing at a very high rate. To enhance their productivity, address the international quality standards, and remain competitive in the international markets, manufacturers are investing in technologically advanced lamination systems. Cost saving and green production are also achieved through energy-saving designs and automation.

Maintenance and Operational Reliability

Although they are highly sophisticated, the Modern Lamination Machines are designed to be simple to service, and they have a long working life. Good quality components, convenient layout of machines, and effective lubrication systems minimize the breakdowns and time spent on maintenance. Routine service maintains a steady lamination performance and increases the life of the machine.

We say that

High-technological Industrial Lamination Machines are needed by the manufacturers who want to gain high-quality products, high efficiency, and high performance. Modern Lamination Machines facilitate continuous production in industry as well as a variety of application requirements by incorporating precision engineering, automation, and high-speed operation. The adoption of high-tech lamination technology can help businesses to add value to their products, lower the costs of operating a business, and become successful in the current competitive industrial environment in the long run.