In converting and manufacturing industries today, effective management of waste is equivalent to manufacturing. Given that slitting, coating, lamination, and printing processes are continually occurring, edge trims and side waste are therefore produced. The solution to this trim waste is the Automatic Trim Winder Machine, which is a specialized device to collect, wind, and control this waste. A Trim Winder Machine has become a must-have machine in industries that wish to have a clean operation and continuous production.

What Is a Trim Winder Machine?

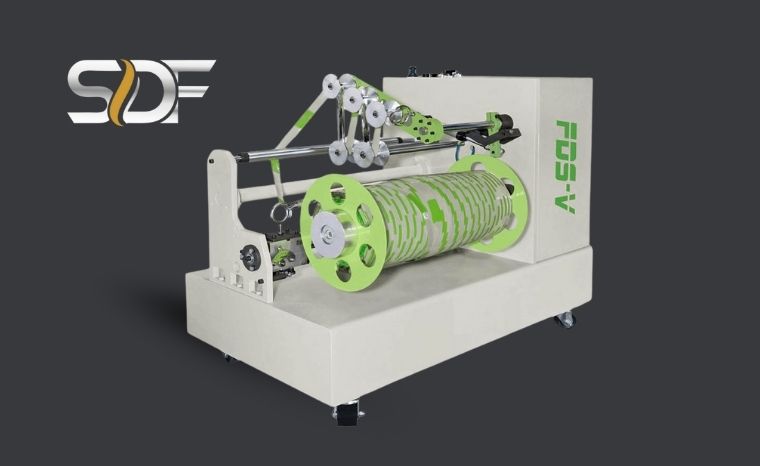

Winding of edge trims and scrap material that is produced during continuous production processes is done on a Trim Winder Machine. The machine does not leave waste on the ground as it is neatly rolled into a small roll. The automatic trim winders will be synchronized with the main production line, and the continuous waste will be collected automatically without any human touch.

The relevance of Automation in Trim Winding

Automation is important in enhancing efficiency and safety in the workplace. The Automatic Trim Winder Machine does not require the manual handling of waste, and this saves labour and avoids accidents. The machine automatically changes the winding speed and tension to achieve a steady hand winding even in high-speed industrial applications. This will ensure that the production environment is clean and will avoid wastage that leads to downtimes.

The main characteristics of automatic trim winder machines

The Trim Winder Machines of the modern generation have sophisticated characteristics to suit the needs of industries:

- Automatic tension control during uniform trim winding.

- Fast working with continuous production lines.

- High and robust, long working hours.

- Small design to conserve floor space.

- Convenient control panels with easy monitoring.

These characteristics render automatic trim winders consistent and efficient in very demanding industrial tasks.

Industrial Applications

Automatic Trim Winder Machine is commonly used in the flexible packaging, plastic films production and paper processing, production of aluminum foil, coating lines and lamination units. Constant trimming is inevitable in such industries, and wastage management is of the essence. The Trim Winder Machine makes sure that the side trims are picked up in one place, making it easy to dispose of or recycle at a lower cost.

Industrial Manufacturers Benefits

An Automatic Trim Winder Machine has a number of benefits to manufacturers:

- Better housekeeping and cleaner working conditions.

- Less handwork and moving around.

- Constant and continuous production.

- Reduced and sizeable waste bundles.

- Improved efficiency of the plants as a whole.

Through more efficient trim waste management, manufacturers can give more attention to productivity and quality control.

Position in Batching Production Lines

Interrupted production is also necessary in industrial settings that are often high-paced. An Automatic Trim Winder Machine is used in ideal coordination with slitting, coating or lamination machines. It automatically self-adapts to changes in line speed, keeping the trim winding at a consistent pace throughout the process. Such synchronization prevents the stalling of production and aids in flawless, uninterrupted production.

Durability and Maintenance

Trim Winder Machines are of industrial construction. The use of quality parts, strong frames, and an effective drive system makes them durable even when used regularly. These machines are easy to maintain, although they are of heavy-duty construction. Mechanisms of simple roll change and the availability of parts minimize downtimes and contribute to the preservation of operational efficiency.

Increasing Trim Winder Machine Demand

As more manufacturing and converting industries are becoming more automated, the need to find effective solutions to waste management is increasing at a very high rate. This is addressed by an Automatic Trim Winder Machine because it is reliable, efficient, and easy to use. More and more industries would tend towards cleaner and more sustainable production methods, and in this case, trim winders are also helpful in segregating the waste and recycling it.

We say that

Automatic Trim Winder Machine and Industrial use is a critical solution to control the wastage of trim in the modern manufacturing industry. The Trim Winder Machine promotes overall production efficiency by reducing the time spent on controlling the wind of waste, increasing the standards of cleanliness, and facilitating the functioning of the processes throughout the day and night. High-quality automatic trim winder is a cost-effective tool that enables industries to save downtime as well as enhance safety and a well-organized production floor, so it is an indispensable aspect in the current industrial life.